This is Smart Factory.

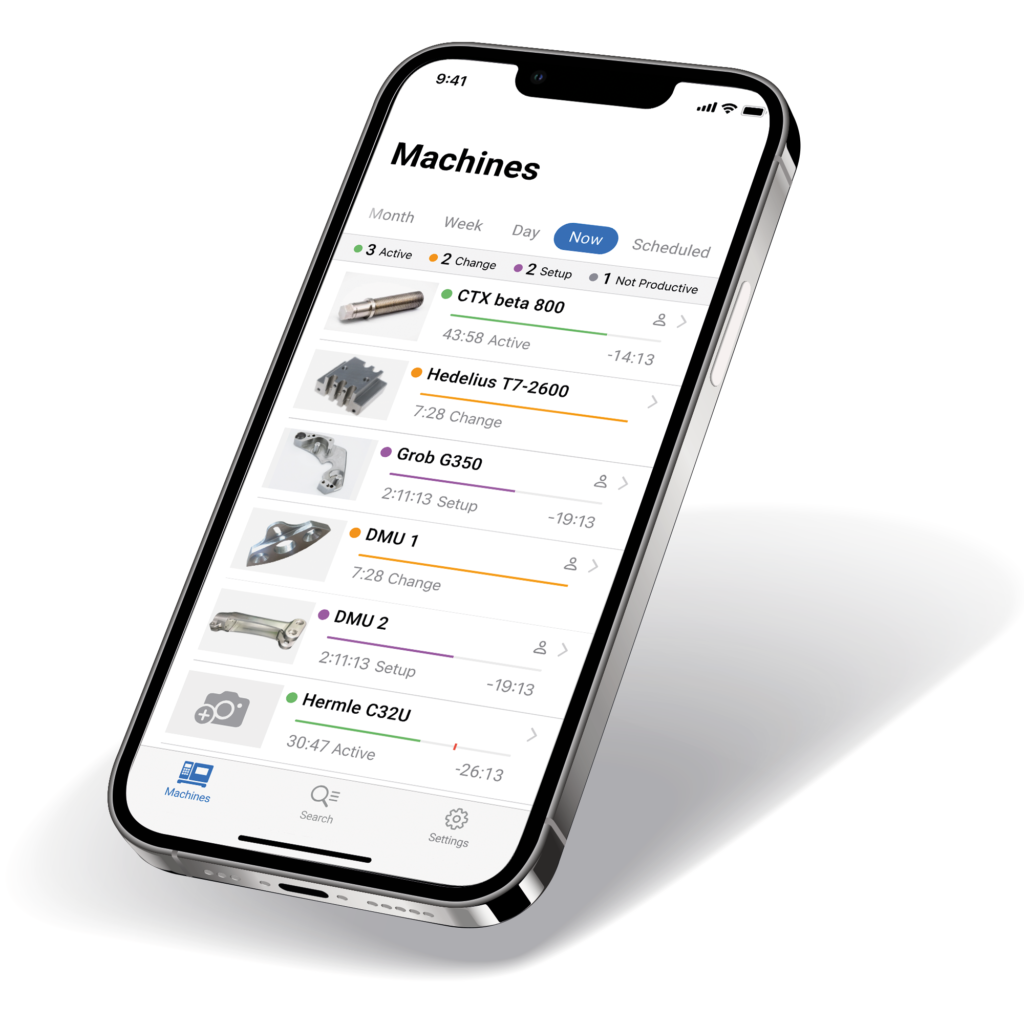

Insight into your factory at a glance

We are a young team of smart and enthusiastic people who want to make factories do business. Through our smart software solution to process data, we ensure that insight into the plant is presented in an easy and user-friendly way. We see the software as a butler: it is at your service and it helps you.

We have a free version. No credit card required.

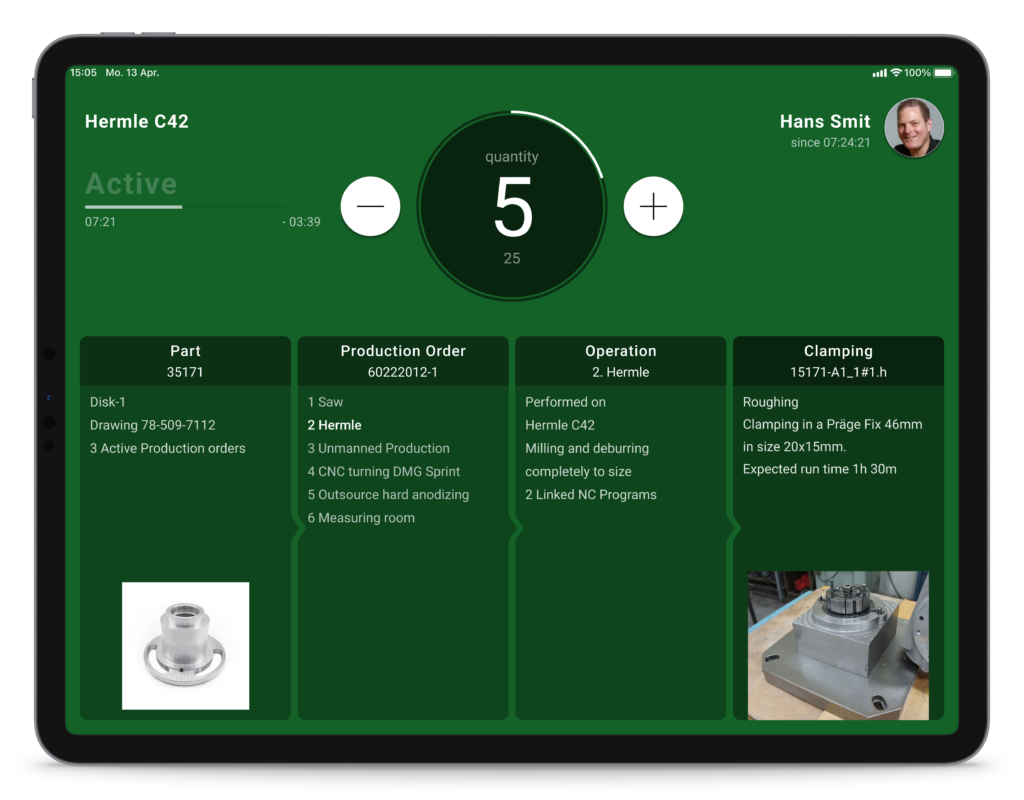

We see that businesses owners have to go to great lengths (or have them go to great lengths) to gain some insight into the factory. The data obtained is often incomplete and too late. As a result, it has no value. A waste of time. We take care of getting the data out of the factory to transform it into useful information. But in a smart way that lets the machines do the work and not the people.

Smart and efficient app

Factory insights

User friendly

The way we work and the design of the software is of contemporary times. It will remain so; we move with the technical developments. In addition, we meet the need to exchange data with other applications. We are open to linking with other parties in a standardized way in order to store and maintain data only once.

Our challenge is and remains that our software is an unmissable tool for factories.

We have a free version. No credit card required.

Partners

[mk_theme_module folder=”partners” file=”partners-overzicht”]